Features

Save Environment, Save Energy, Save Eareh

The company dedicated to recycling business

![]() Home > Product > Features

Home > Product > Features

- Chip Treatment Method

- Improvement Effect

- Corporate environmental improvement and cost reduction are guaranteed.

Existing chip storage space is minimized by compressing and reducing cutting chips to a maximum 1/50,

Existing chip storage space is minimized by compressing and reducing cutting chips to a maximum 1/50,

significantly increasing space utilization rate. Cutting chips and cutting oil are not spilled onto the factory floor, ensuring a clean workspace at all times.

Cutting chips and cutting oil are not spilled onto the factory floor, ensuring a clean workspace at all times. Cost reduction is achieved by compressing chips generated after machining, recovering 98% of the cutting oil

Cost reduction is achieved by compressing chips generated after machining, recovering 98% of the cutting oil

contained in them, and recycling it through a filtration system.- Compressible materials

Nonferrous metal such as aluminum, copper, etc. / cast steel, cast iron / steels such as SS, SC, etc. / Stainless, miscellaneous metal

Nonferrous metal such as aluminum, copper, etc. / cast steel, cast iron / steels such as SS, SC, etc. / Stainless, miscellaneous metal- Effect of cutting oil recovery

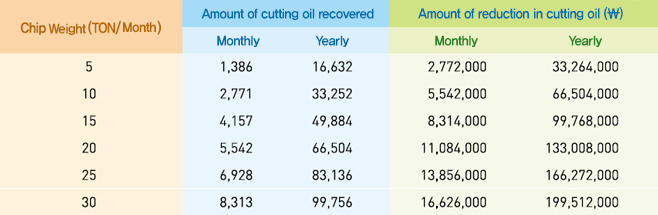

EX) 1. Compression material : Aluminum

EX) 1. Compression material : Aluminum- 2. Machining equipment : Automatic rack/MCT/General-purpose rack, etc.

- 3. Cutting oil used : Neat cutting oil

- 4. Unit purchase price of cutting oil : 2,000 (per 1 ℓ)

주석) 1. Recovered cutting oil weight after compression is estimated at 23% of chip weight before compression.

주석) 1. Recovered cutting oil weight after compression is estimated at 23% of chip weight before compression.- 2. Recovery rate, production capacity may vary depending on the quality of compression material and type.

- 3. Note the outcomes are from in-house testing.

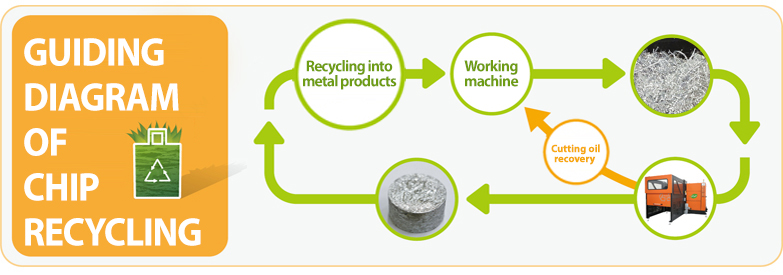

- Guiding Diagram of Chip Recycling